www.Maschinenbau-Schmidberger.de

Sonderbau in Stahl und Edelstahl

www.Maschinenbau-Schmidberger.de

Sonderbau in Stahl und Edelstahl

www.Maschinenbau-Schmidberger.de

Sonderbau in Stahl und Edelstahl

www.Maschinenbau-Schmidberger.de

Sonderbau in Stahl und Edelstahl

products

Sloping insertion

An important element for the entire biogas plant

In order for the energy crops as well as the organic residues to be used functionally, a high-quality injection technique is an important component. Without these solid matter feeders, it is not possible to keep the functionality of the biogas plant running and to ensure that the materials are completely processed.

Funnel system

High conveying performance due to the hopper system

When it comes to the coordinated and smooth production of biogas, our plants are the perfect choice. Their use makes it possible to use energy crops and animal excrements to produce the gas and at the same time homogenise the liquid substrates.

To fully utilize the own plant, the dosing system is then used to ensure a connection with the solid substrates and to optimize the biogas production. For a safe biogas plant feeding, we offer the highest level with our technical components.

Moving floor feeder

High-quality moving floor feeders for every biogas plant

When a large storage volume must be achieved in the feeding technique, the push floor feeder is a good choice. It allows to increase the production of biogas and to facilitate the transport into the fermenter.

Scraper floor feeder

Our systems for processing in the scraper floor

When it comes to processing complex and difficult to dose substances and materials, the scraper floor systems are a good choice. They provide energy-saving and safe operation without the need for wear and tear or other stress within a very short time.

Liquid feeding

Our feeding pump for gas production in the plant

If the biogas plant is to be fully operational, there must be no lack of a suitable pump for liquid feeding. This enables an effective mixing with the substrate to be introduced, which enables a transfer to the fermenter.

Screw Conveyors

Easy transport through our screw conveyors

We are your partner for the supply of precisely fitting screw conveyors. They make it possible to forward the substrates in a coordinated manner and are thus the link between the different areas of the biogas plant. For this reason, it is important that they also fit technically to the design of the plant, so that safe conveying is possible. With the production from V2A stainless steel you expect durable and extremely robust machine parts.

Beet shredder

Our shredder for filling the fermenter

With our modern beet shredder, we enable an effective shredding of individual beets as well as a comfortable filling of the solids dosage unit. Thus, the shredder becomes an important part of the functional operation of the biogas plants in order to use the many agricultural products for biogas production quickly and easily. Thanks to its enormous efficiency, the shredder is also suitable for beets that are difficult to shred, which makes fast and targeted shredding possible.

Gas treatment

With our gas treatment for sustainable plant operation

A professional and appropriate treatment of the resulting gases plays an important role in improving structure and sustainability. In the field of environmental technology, our modern treatment systems are therefore a good approach to both simplifying cooling and improving filtration. With our design, it is therefore possible to provide noticeably more comfort in the daily use around the operation of the biogas plant.

Exhaust gas heat exchanger

Our heat exchanger to extend the performance

Many plant operators face the challenge of maintaining the efficiency of their own biogas plant. The problem here is that the required output is not available, especially when there is a high demand for heat, which is why a convenient solution is needed for using other forms of heat. This makes it possible to use the plant for district heating, residual heat or many other applications and to improve efficient operation.

Special constructions

High quality offers in the field of special constructions

The Liquidmix for mixing liquid and solid materials

The Liquidmix makes it possible to transfer mixtures of liquid and solid substances to the pump. This is achieved within two dissolving shafts, which ensures uncomplicated transport to the cutting unit. Thanks to the combination of the two substances, a homogeneous feed mash is created which can then be passed on to the fermenter. All around the Liquidmix as a connection between liquid feed and solid dosage unit, a high-quality and structured solution in the feeding technique is thus offered, which does not lack performance. Those who want to use a robust and at the same time powerful mixing technology themselves are secured with the Liquidmix.

Stairs and landings

Modern solutions for testing and maintenance

In large biogas plants it is often difficult to reach all areas without additional stairs or a platform. For this reason, we offer you an enormous comfort and support you with our devices and maintenance walkways to have a safe overview of every area of the plant. Thus, there is nothing standing in the way of a well-planned and comfortable execution of the tests, in order to be safe both as employee and within the inspection.

Drum filling station

Our drum filling stations for easy filling

Functional and safe technology is essential so that the barrels can be filled with the fermentation substrate from the biogas plant. The drum filling station offers a convenient solution for filling, which is located on the fixed base plate.

This means that stability and support are of paramount importance to ensure smooth and extremely convenient filling. Safe and structured filling is thus possible at any time around our systems.

Mobile drum filling station

Maximum flexibility with our mobile drum filling station

With our mobile drum filling station, we make it possible to fill the drums quickly and efficiently with the available fermentation substrate. Our systems offer an enormous technical quality and meet all requirements.

Thus, we offer comfort and safety within the entire application, so that there are no more obstacles during filling. For the structured use of the biogas plant, our offer of various conveying stations is a good choice.

Pipeline construction

Pipelines for your biogas plant

For the correct and functional operation of a biogas plant you need pipelines that connect different systems. For this reason, we have made it our business to manufacture all conceivable piping systems. In order to do this, we adapt as flexibly as possible to existing requirements and enable our customers to carry out functional processing. Thus, gas pipes, substrate pipes and fittings fit the nature of the plant with certainty.

Substrate heater

Our substrate heater for the biogas plant

If constant temperatures in the fermenter are required, an additional heating system may well be worthwhile. This makes it possible to keep the operating temperature constant and to be able to rely on an even gas production at any time of the year.

For this reason, it is not only worthwhile in winter to fall back on a comfortable fermenter heater in order to extend the comfort of using your own biogas plant as well as to easily adjust the temperature.

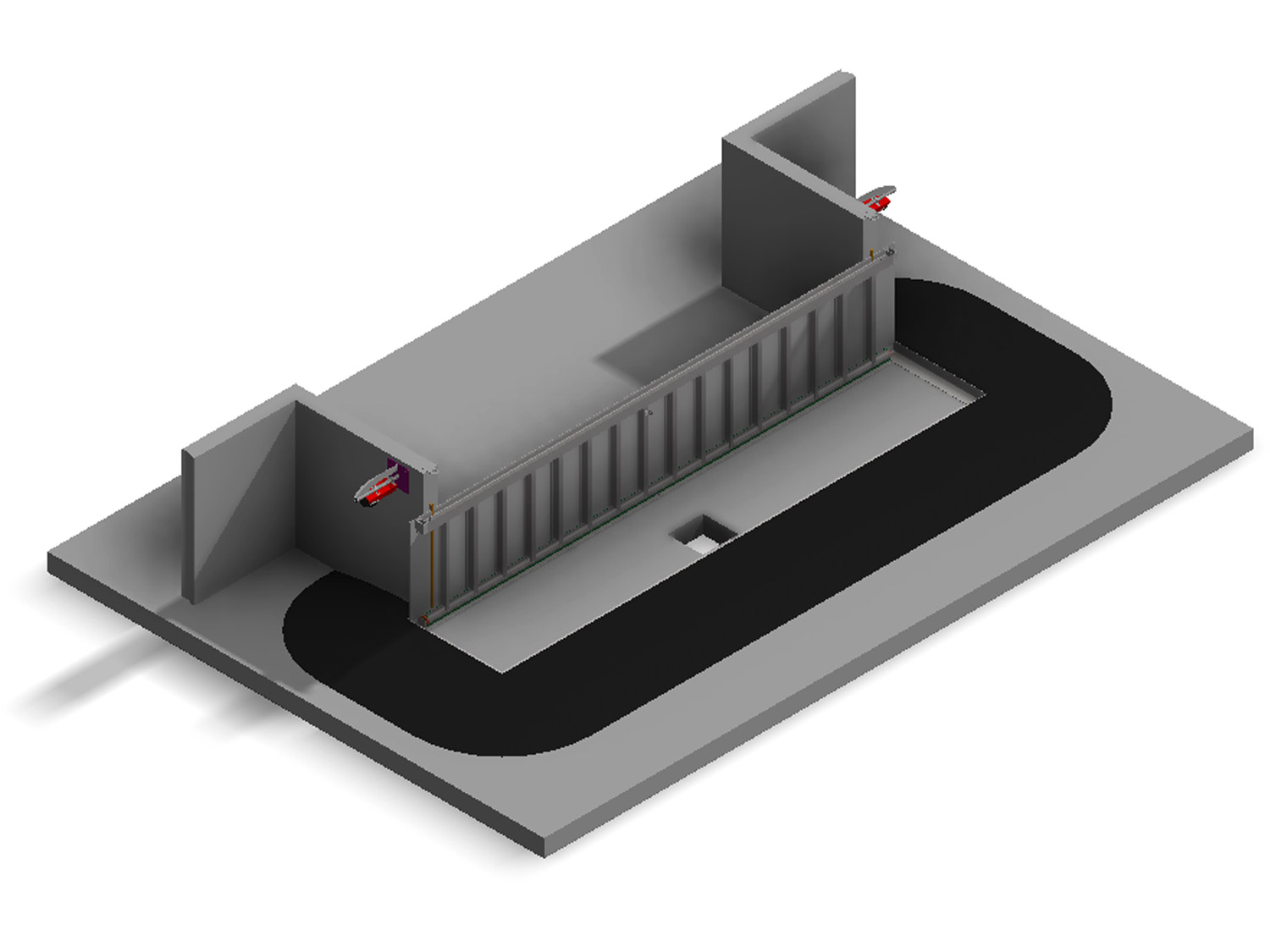

Emergency lock

Our emergency lock for shielding in case of accidents

To be on the safe side in the event of an accident, a structured lock system is essential. In this way, it is possible to avoid that the resulting damage affects the entire environment of the biogas plant and disrupts continued operation. For this reason, our new product offers enormous protection and ensures that a quick and well thought-out reaction is possible in all conceivable emergencies.